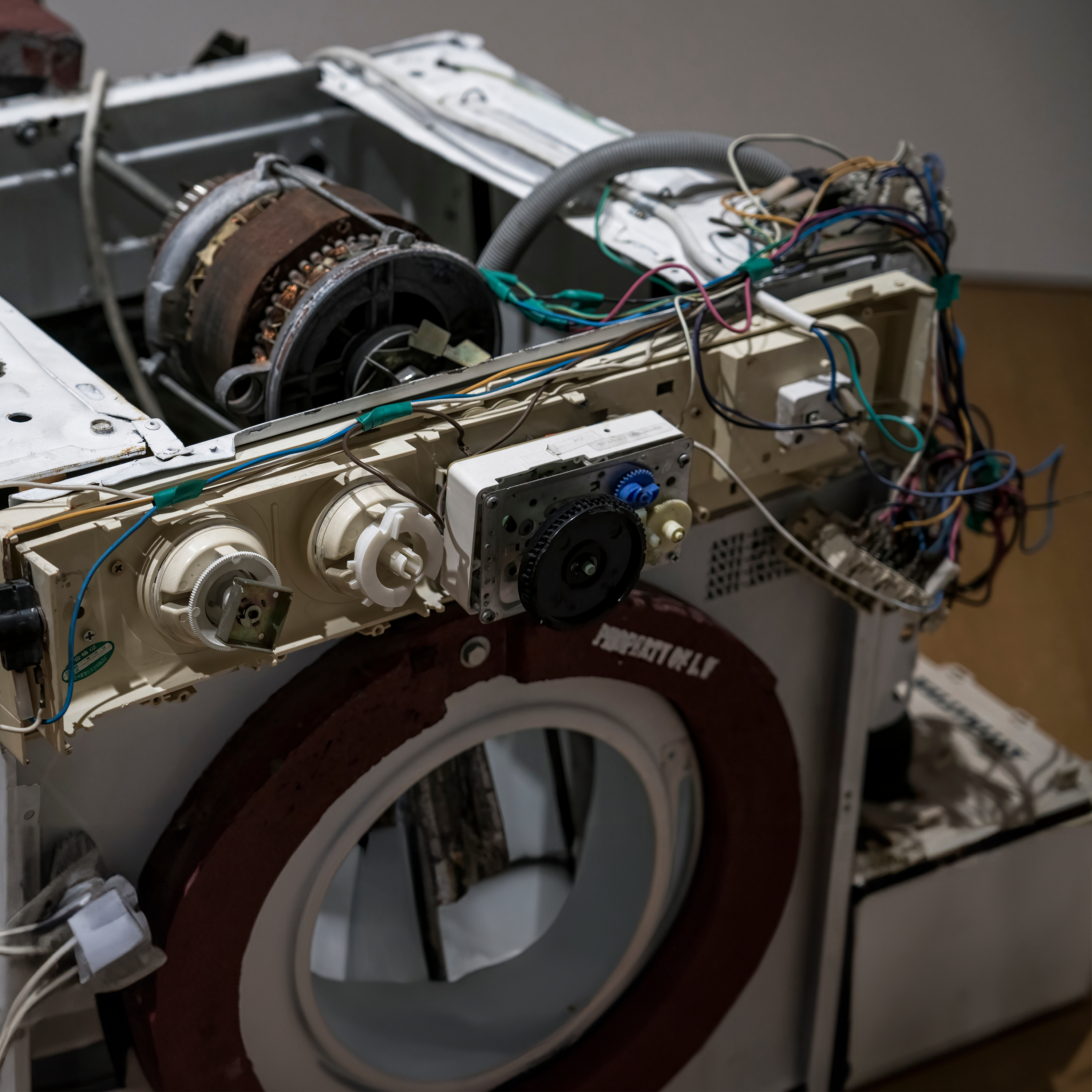

Closing the Loop: (Re-) Design for Disassembly and Circular Economy

3 – 7 June 2024

This summer school aims to analyze the possibilities of designing for disassembly and remanufacturing systems to increase life-spans and circularity of products.

Image credits: retrieved from Adobe Stock, by Steve

Keywords: sustainability, production chain, circular economy, disassembly

Location

RWTH Aachen, Germany

Participants

Application is open to Master and PhD Students of the member universities from the IDEA League Alliance.

Expenses

There are no registration and accommodation fees. Students from IDEA League member universities selected to participate in a summer school only have to pay for their own travel costs where applicable.

Requirements

Curriculum vitae & publication list

Letter of motivation

Letter of recommendation (optional)

Supervisor approval (only for PhD students from Chalmers)

Course Content

One of the main strategies to achieve sustainable, green production is a circular economy. To close material life cycles, the EU is currently passing multiple legislations that regulate reparability, recycling quotas, and digital product passes for a range of products. Substantial financial and ecological potential lies in remanufacturing of components and materials. Design for Disassembly (DfD) is a useful tool in this context and an emerging field of research. Moreover, the implementation of automated disassembly systems will enhance conventional manual systems and enable a wider range of strategies, such as remanufacturing, to scale it into a profitable business case.

Today, product design and designing for end-of-life are still separated in common practice even though “smart” product design and adapted production systems are the most powerful tools to facilitate practical end-of-life revalorization. This summer school aims to overcome this barrier and make product designers and system planners aware of their potential impact.

Learning Objectives

Students will learn:

- when and why to use DfD.

- how can design make reusing, remanufacturing, repair, recycling easier.

- how automated, flexible remanufacturing systems can be used to implement efficient remanufacturing.

- what are practices in the industry today (especially the automation of systems).

- how can opposing goals be overcome (i.e. designing for long life vs. DfD).

- how can longer lifecycles (including repair or redesign by users) be facilitated.

Further goals of the summer school:

- Encourage formation of networks between the universities regarding green technologies.

- Encourage exchange about own fields of studies.

- Encourage sharing of learned information and experience through participants.

Schedule

Day 0: Sunday: Arrival and networking

Day 1: Monday: Introduction to circular economy: design and assembly in manufacturing

Day 2: Tuesday: Disassembly Mapping

Day 3: Wednesday: Automated remanufacturing systems and redesigning a product for disassembly

Day 4: Thursday: Remanufacturing (dis-)assembly systems

Day 5: Friday: Closing day with presentations and networking