HOT – Healing Our Towns

8 – 13 September 2025

The 2024 climate crisis, marked by extreme heat in Lombardy and northern Italy, calls for urgent adaptation strategies. This workshop invites students to explore how small and medium-sized towns like Crema can adapt to climate change by focusing on the redesign of public spaces to tackle heat, water scarcity, and new urban questions. Participants will meet experts, engage with local administrations, and experience firsthand the impact of climate change while imagining radical solutions for the future of cities. A preliminary online meeting is scheduled in July. The workshop will begin on the first day with a seminar in Milan. For the following days, activities will take place in the city of Crema, where students will also stay overnight.

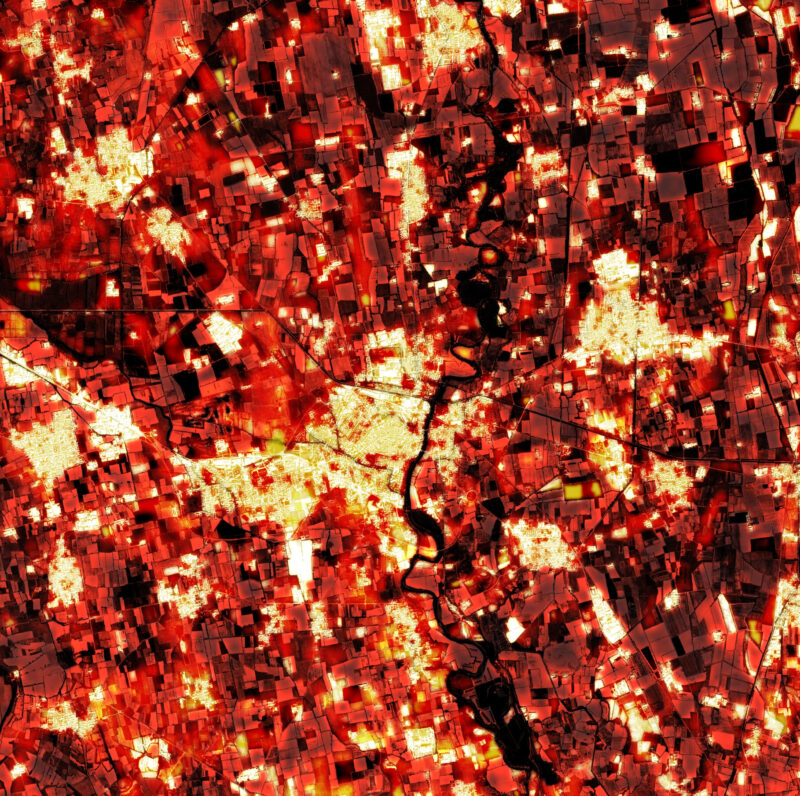

Image Credits: Re-elaboration of LANDSAT data by Marco Voltini, Ettore Donadoni, Cristiana Mattioli.

Keywords: Climate change, heat, water scarcity, urban adaptation, public spaces, urban redesign, rural challenges, migration, agriculture, sustainability, resilience, city future, environmental impact, adaptation strategies.

Location

Crema, Italy

Participants

Application is open to Master and PhD Students of the member universities from the IDEA League Alliance.

Expenses

There are no registration and accommodation fees. Students from IDEA League member universities selected to participate in a summer school only have to pay for their own travel costs where applicable.

Requirements

Curriculum vitae (For the selection process, we ask applicants to provide a CV that includes a list of the exams they consider most significant for their education (from 5 to 10)).

Project Portfolio or Publication list. We also require the submission of a project portfolio or a list of publications. In both cases, for works created by multiple authors, the applicant’s contribution to the final product must be clearly highlighted.

2024 has been the hottest year on record globally (for now). In the Lombardy region, the annual average temperature anomaly for 2024 is +1.5°C compared to the 1991-2020 reference period. The hottest month was August, with +3°C compared to the climatological average, making it the second hottest August since 1991, only surpassed by August 2003 (ARPA Lombardia, 06/09/2024). The climatic conditions in Italy are changing. Northern Italy, from the Po Valley to the Alps, is one of the key regions where climate change can have a serious and detrimental impact, with severe consequences for water, agricultural yields, and human health, especially for vulnerable social groups. Some research is beginning to imagine future scenarios of internal vertical migration, with temporary or stable groups of people moving from the hot, polluted, and dry plains to the mountains (Membretti et al. 2024). The signs of these processes are currently weak but present, while the needs of the 20 million people who live and will continue to live here are more visible and urgent. How can we ensure these places’ future liveability and quality of life? How can natural resources and agricultural land be preserved? How can cities adapt to this permanent new condition and be more equal? These issues are particularly challenging for intermediate territories, such as small and medium-sized towns in rural areas, where buildings in historical centres are losing value, the public welfare system is under pressure, mobility is essentially dependent on the car, old abandoned spaces coexist with new productive and logistical expansions, and agriculture is highly mechanized and industrialized. This workshop invites students to reflect on different visions of the future and imagine how adaptation strategies will change our cities, starting from their public and open spaces. Looking at the specific local situation of Crema, a town of 30,000 inhabitants in the centre of the Lombardy region, 50 km from Milan, we will explore radical approaches and solutions for healing cities by using existing spaces and resources differently. We will meet experts, practitioners, and local administrations dealing with heat, water scarcity, and climate change. We will explore places and talk to people. We will engage with different themes, urban conditions, and materials. We will experience the fatigue of hot summer days.

Learning Objectives

- To explore adaptation strategies for middle cities and rurban (rural and urban) territories facing climate change.

- To redesign public and open spaces in response to climate challenges.

- To engage students in the local context of Crema, a town affected by heat and water crisis.

- To involve experts, local administrations, and community members in the adaptation process.

- To raise awareness about the future of urban spaces and the challenges of climate change in small towns.